Our “Future of Packaging” initiative

Absolut Vodka is spearheading the group-wide Future of Packaging programme reflected by reaching a significant milestone on its journey to create a 100 per cent bio-based bottle.

We are challenging the idea of packaging as we know it. By bringing together leaders across the group we are pooling everyone’s inspirational ideas to find alternative solutions that will be more sustainable and better connected. Our vision for the future of packaging revolves around three core themes: no waste; hyper personalisation; and future drink experiences.

“It’s our responsibility to try to limit the environmental footprint of our packaging. Generating ideas for packaging with purpose derives from three core paths, with ‘no waste’ the path with the biggest environmental potential,” says Elin, Director of Future Packaging at Absolut.

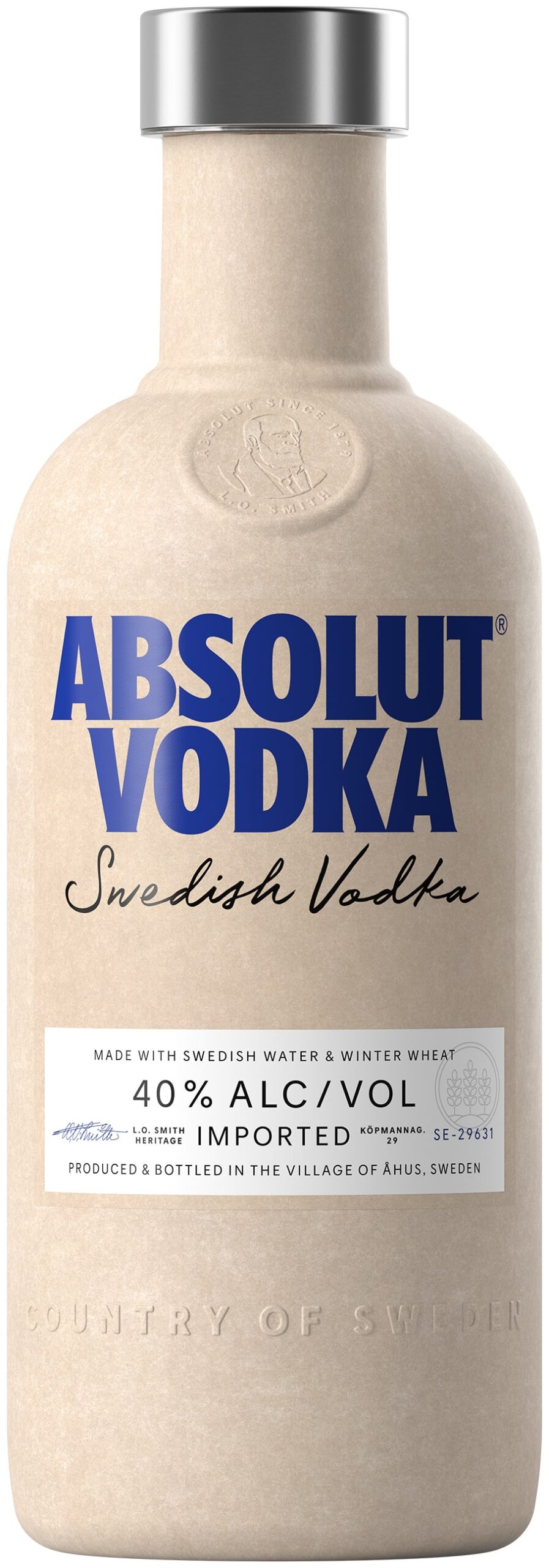

When it comes to the ‘no waste’ path of the Future of Packaging initiative, Absolut Vodka is leading Pernod Ricard’s charge for a 100 per cent bio-based bottle. Our first trials began in late 2020 at festivals in the UK and Sweden and in 2023, we put our single-mould paper bottle to the test on supermarket shelves.

Made from 57 per cent paper with an integrated barrier of recyclable plastic this was the first time single-mould bottles had been sold commercially in-store by a global spirits company. Unlike our initial pilots, where we tested our low ABV Absolut Mixt ready-to-drinks, this bottle was tested using the higher 40 per cent ABV of Absolut Vodka.

The test is an integral part of our vision for single-mould paper-based bottles to become part of our packaging portfolio, complementing our iconic glass bottle rather than replacing it. While standard glass bottles are also recyclable, our paper-based bottles are currently eight times lighter and easier to carry. We believe consumers will use them for different occasions, be it at home, on picnics, at a festival or anywhere in between.

“This is a journey towards a 100 per cent bio-based bottle. We know that this current bottle isn’t the end solution. It is a stepping stone,” says Elin Furelid, Director of Future Packaging at Absolut. “And while this test is for Absolut Vodka, we are researching what brands could be next. If this works for a white spirit such as vodka, then it could work for gin, tequila or why not whiskey. The purpose of Future of Packaging isn’t brand specific – it is scalable to others across the group.”

Trial in the UK

The trial began during the summer at a selection of Tesco supermarkets in Manchester, northern England because the city had the recycling infrastructure to handle the bottles. Feedback was very positive – sales were consistent, and consumers appreciated the initiative. Notably, we have found across all our tests that many consumers and bartenders are initially sceptical about the bottle’s functionality – reservations that likely stem from past experiences with subpar paper products, like the early versions of soggy paper straws. However, we have found this scepticism disappears once people use our paper-based bottle.

More tests are in the pipeline. We’ll be testing the bottle on long-distance shipping transport to see if it scuffs up more than a glass bottle on a two-month journey and testing bigger volumes. The next step is to develop a new paper-based bottle with a reduced plastic barrier that will be 85 per cent paper, with potentially a fibre cap too.

The paper bottle initiative is part of a wider collaboration with Paboco (the Paper Bottle Company) and their community of global brands The Coca-Cola Company, Carlsberg, P&G and L’Oréal – to work collectively to help the drinks and packaging industries push the boundaries for sustainable packaging.

“We want consumers and partners to join our journey towards a more sustainable future. Together we can develop packaging solutions that people want and the world needs. That’s why bold partnerships to test the waters are going to be evermore crucial on our net zero journey,” adds Elin.

If this works for a white spirit such as vodka, then it could work for gin, tequila or why not whiskey. The purpose of Future of Packaging isn’t brand specific – it is scalable to others across the group.

Elin Furelid Director of Future Packaging

Our collaboration with Swedish-based Blue Ocean Closures (BOC) to develop a natural fibre-based screw cap for Absolut Vodka bottles has reached a significant milestone – we can now hold the prototype paper cap in our hands.

The cap is a cellulose-based screw cap that is durable, strong and water-resistant – made from renewable and recyclable wood fibres. The cap is intended to be recycled in the regular paper recycling stream and the long-term ambition is to be completely biodegradable. Over time, a fibre-based cap could help cutting carbon emissions by 80 per cent.

“Theory has gone into practice. We now have a prototype paper cap that we can hold in our hand, screw onto a bottle and turn the bottle upside down to test if it leaks,” says Eric Näf, Director of Packaging Development at The Absolut Company.

The Absolut Vodka initiative forms part of the Pernod Ricard Group’s ambition to create a fully circular business, working with suppliers and partners to ensure that 100 per cent of its packaging is reusable, recyclable or compostable by 2025. Subsequently, the move to a fully recyclable bottle cap is moving fast but further prototypes will be tested before the new cap is on the shelves of shops and bars.